-

Product DescriptionCompany Info.<>

- Model:

- ZWIN-CEMS

- Processing customization:

- Yes

CEMSflue gas online monitoringproduct introduction

I.System overview

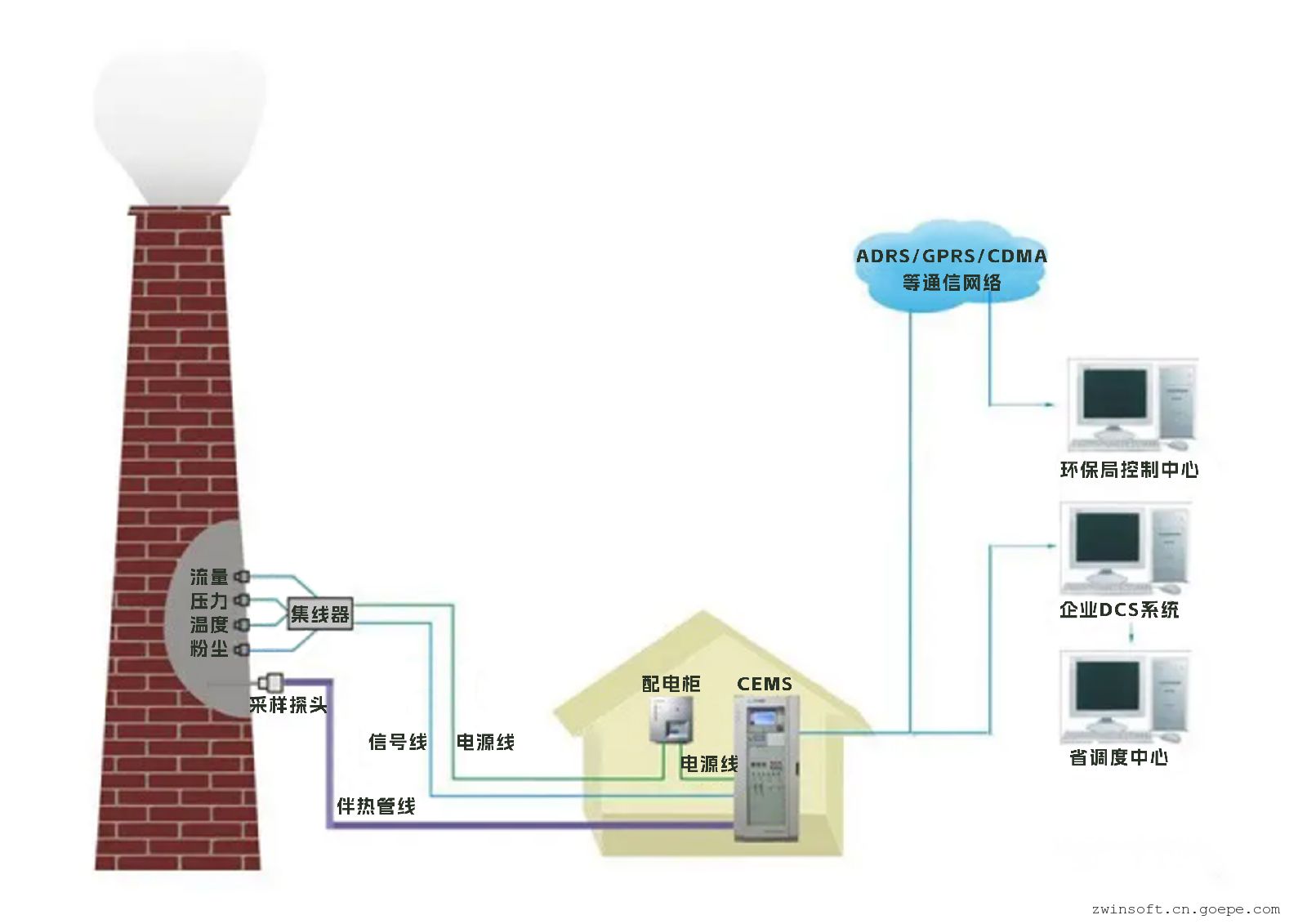

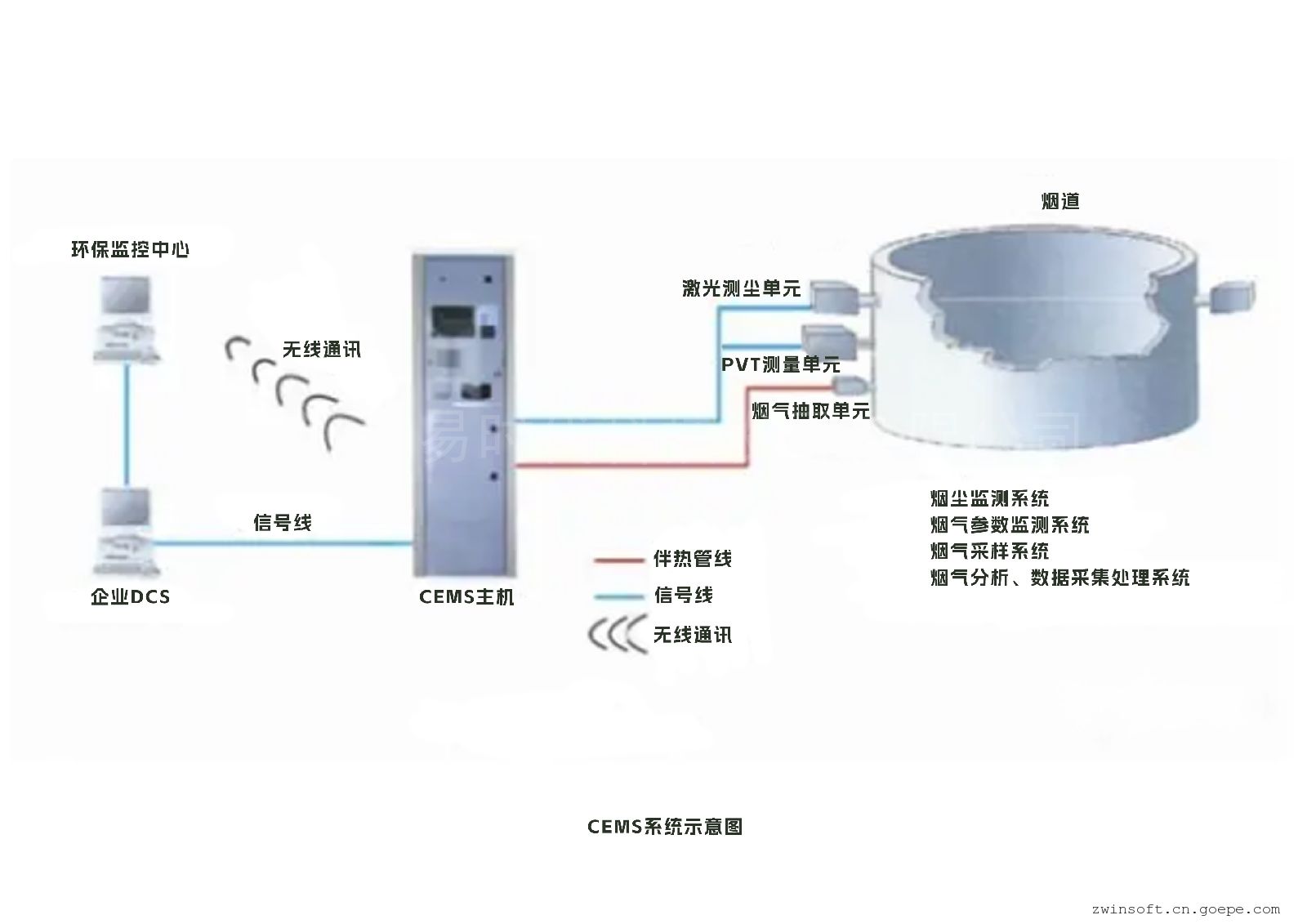

CEMS is mainly composed of flue gas parameter measurement subsystem, particulate matter CEMS, gaseous pollutant CEMS, data acquisition and transmission units, forming an integrated system integrating data acquisition, processing, display, communication and remote monitoring.

The continuous monitoring system for flue gas emission consists of particulate matter measurement subsystem, gaseous pollutant measurement subsystem, flue gas parameter measurement subsystem and data acquisition and analysis subsystem. Through direct measurement and analysis (particulate matter) and sampling method (gaseous pollutants), determine the concentration of pollutants in flue gas, and simultaneously determine flue gas temperature, flue gas pressure, flue gas flow rate, flue gas oxygen content and emission amount; report showing various monitoring parameters.

1. Particulate matter measurement subsystem

Smoke detector; determination of smoke content. Includes: host, probe. Signal output:4-20mA

2. Gaseous pollutant measurement subsystem

(1) Gas analyzer with calibration function. Calibration time and cycle shall be determined according to site conditions.

(2) Sampling probe, with self-heating and temperature control functions.

(3) Temperature control tracing sampling pipeline, sampling pipe material is PTFE.

(4) Pretreatment system includes: refrigerator, drainage pump, anti-corrosion sampling pump, precision filter, electromagnetic valve, etc.

3. Smoke parameter measurement subsystem

(1) Temperature, pressure, flow rate and other online monitoring instruments.

4. System control, data acquisition and data processing system

(1) Data acquisition and processing system hardware

(2) Flue gas emission continuous monitoring system software

II.Functional characteristics

(1) Directly analyze the original, keep the physical and chemical characteristics of the flue gas as much as possible, and the sample gas is representative;

(2) Back-purging function: SO2/NOx/O2 sampling probe of CEMS, emission end and receiving end of smoke meter have purging function; it can back-purge the outer surface and interior of probe to reduce particle adhesion. Design: Helical airflow purges the probe cavity to eliminate probe maintenance and particulate matter that has been sucked into the probe cavity;

(3) Indication function: In addition to indicating the self-diagnosis and alarm contents mentioned above, the data acquisition and transmission system can also display the analyzer in the calibration cycle, the calibration cylinder low pressure, excessive calibration error and other contents;

(4) CEMS can be unattended for a long time;

(5) Other functions: self-diagnosis, automatic control, automatic calibration, system networking, error code indication, etc. of main analytical instruments;

(6) Data processing system: The CEMS system independently developed by our company meets the national environmental protection requirements and the data acquisition, control and processing system of the Technical Specification for Continuous Flue Gas Monitoring System of Thermal Power Plant. For details, please refer to the introduction of data acquisition and transmission system;

(7) CEMS has high reliability, safety, maintainability and scalability. The monitoring equipment meets the operation requirements of two sets of flue gas component sampling probe systems, and certain interfaces and capacities are reserved in the design scheme. CEMS can communicate remotely with the local area network of power plant, power bureau and environmental protection bureau;

(8) The configured software is compatible with the hardware resources of the system. In addition to the system software and application software, online fault diagnosis and antivirus software are also configured;

(9) Analytical instruments and monitoring instruments designed by CEMS include electrical signal interfaces for routine maintenance personnel to facilitate maintenance by technicians;

(10) Sampling probe and filter can be automatically anti-purge and remote control anti-purge to prevent clogging; analysis system has automatic and remote gas calibration function; analysis instrument, sampler, heater and tracing pipe heater have automatic fault alarm function;

(11) Intelligent: automatic zero setting, range exceeding alarm, humidity alarm, sampling head temperature abnormal alarm, condenser temperature abnormal alarm, heating temperature abnormal alarm, low flow rate alarm, main maintenance alarm;

(12) Instrument and system log function, record the operating state parameters of the system, and serve as the basis for the accuracy and reliability of the system data;

(13) large screen touch screen industrial control computer, page image, simple operation;

(14) Adopt electric heating temperature control dry direct sampling method, with few auxiliary links and high reliability, which can truly reflect the content of flue gas components;

(15) The system has automatic standard gas test function, which can automatically complete the system check function (remote calibration or semi-automatic calibration), reducing the maintenance workload;

(16) Industrial control computer and PLC control, high degree of automation, can collect detailed state information of the system, can be used as a favorable resource for data validity audit;

(17) It has perfect maintenance reminder function;

(18) There are two sets of databases, one for original storage of original gas station data and the other for data corrected according to relevant national data correction specifications.

III.System advantages

Advantage 1: Infrared absorption gas analyzer adapted to wet desulfurization high humidity low concentration measurement.

Advantage 2: Spiral airflow purges the sampling probe cavity, eliminating probe maintenance and large particles that have been sucked into the probe cavity.

Advantage 3: Real-time monitoring of sampling pipeline temperature and transmission to monitoring platform, low temperature alarm of sampling pipeline can be realized, which is beneficial to remote judgment of fault.

Advantage four: automatic standard Qigong function and remote standard Qigong test.

Advantage 5: Data identification: calibration, maintenance, failure and other states of data labeling, including the temperature of each data record key point, with fault log records, easy to find the problem quickly after a fault occurs.

Advantage six: sample gas pipeline increased flow control valve, flow can be automatically adjusted. Through485 communication remote setting and adjustment of the gas flow through the valve, and output 4-20mA current signal, and can be viewed and adjusted remotely through the platform, to ensure that the sampling flow rate is maintained at 1L/min.

Advantage 7: After the sample gas comes out of the condenser, add a filter with humidity sensor, which is used to alarm when the humidity reaches the set value, and plays the role of secondary filtering sample gas. The humidity sensor can protect the instrument by detecting the humidity in the rear section.

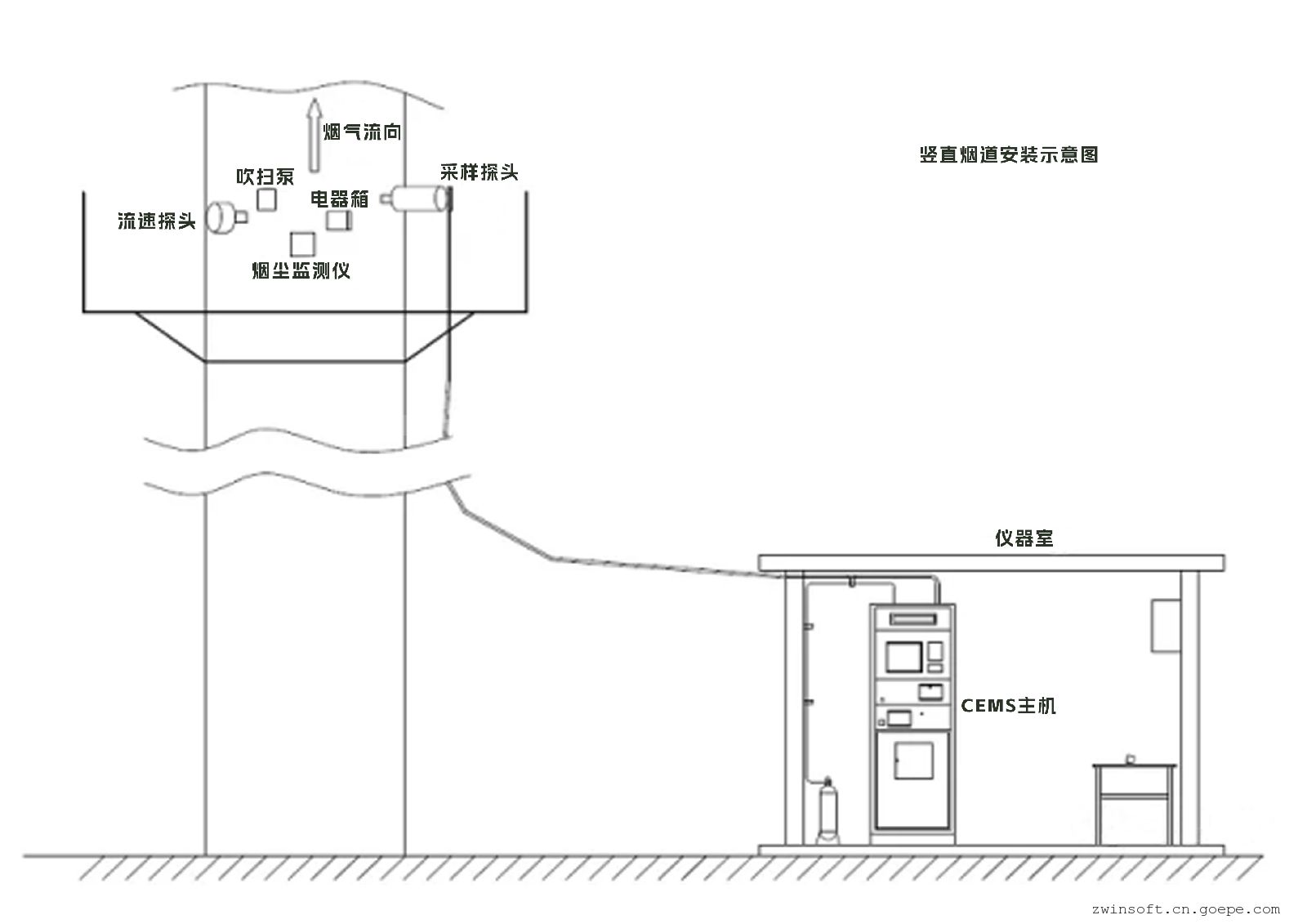

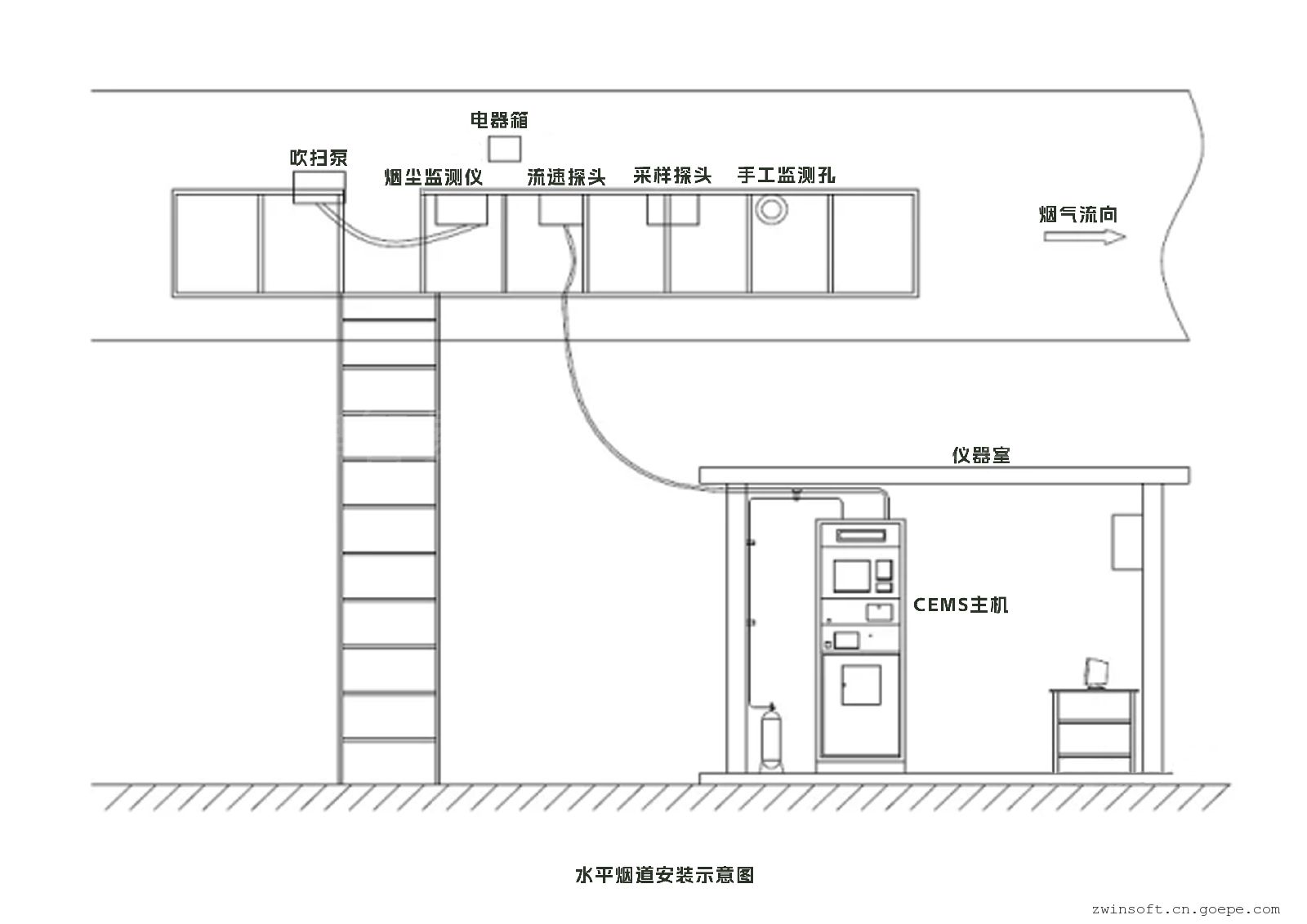

IV.System installation

1. Installation position and site conditions: according to CEMS site conditions confirmation.

2. Measurement points meet the following requirements:

(1) The distance between the measurement points of the particulate matter measurement subsystem and the flue wall shall not be less than 30% of the flue diameter, and the distance between the measurement points of the gaseous pollutant measurement subsystem, oxygen measurement subsystem and flow velocity measurement subsystem and the flue wall shall not be less than 1 m;

(2) Located at or near the centroid area of the flue section.

(3) Set reference method sampling hole for comparison test of reference method.

3. Installation diagram

- Name(chinese)

- Name(English)

- Tianjin Zhiyi Times Technology Development Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Xiqing District, Tianjin, China

- Nearby port

- Tianjin

Tianjin Zhiyi Times Technology Development Co., Ltd. is a high-tech software R & D and information system integration company founded by the doctoral team of Nankai University. It is registered in Tianjin City High-tech Industrial Park. The company is engaged in software development, system integration, software R & D and information system integration in the field of Internet information technology. The company takes Nankai University software as the core of technology research and development, and has strong and strong support in software development and information automation technology. At the same time, it has always maintained good cooperation with Nankai Software School, School of Information, and School of Information of Tianjin University, complementing each other's advantages and promoting scientific research. Transformation of results.- Name(chinese)

- Name(English)

- Tianjin Zhiyi Times Technology Development Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Xiqing District, Tianjin, China

- Nearby port

- Tianjin

Tianjin Zhiyi Times Technology Development Co., Ltd. is a high-tech software R & D and information system integration company founded by the doctoral team of Nankai University. It is registered in Tianjin City High-tech Industrial Park. The company is engaged in software development, system integration, software R & D and information system integration in the field of Internet information technology. The company takes Nankai University software as the core of technology research and development, and has strong and strong support in software development and information automation technology. At the same time, it has always maintained good cooperation with Nankai Software School, School of Information, and School of Information of Tianjin University, complementing each other's advantages and promoting scientific research. Transformation of results. -

Send your message to this supplier*From:*To:

Mr. Dr. Chen(Michael)

*Message:

Mr. Dr. Chen(Michael)

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.